Coil Sheet Machines line

Coil Sheet Slitting and Cut-to-Length Machines

It allows you to load your rolled sheet metal safely and easily with a remote control.

These can be added to your existing uncoiler or to your new uncoiler setup! Optional supports can be added to prevent small rolled sheet metal from tipping over. The rolled sheet metal loading trolley reduces the risk of damage to rolled sheet metal from mishandling and offers a more efficient method of loading rolled sheet metal onto the uncoiler.

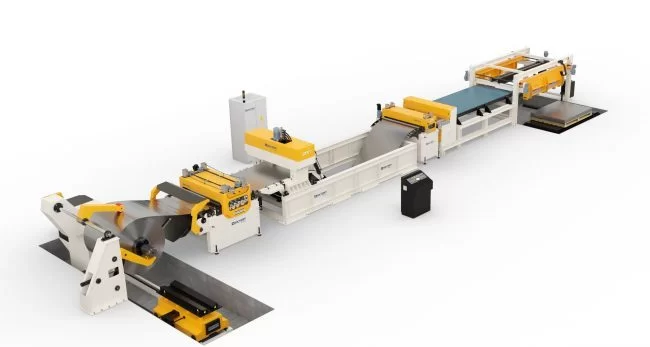

Combined Slitting and Cut-to-Length Line

The Combined Slitting and Cut-to-Length Line offers significant advantages and benefits for the production of a wide variety of products in different industries.

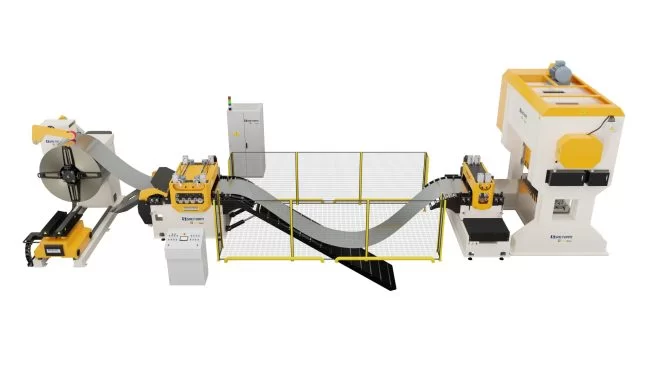

Rolled Sheet Metal Cutting Line

Our goal at SACFORM/Agmline is to increase our customers’ production capacity while ensuring consistent production quality by providing solutions that exceed their expectations and needs through our continuously renewed and improved R&D efforts.

Roll Sheet Metal Cutting Line +Plus

In addition to the features we offer on our standard cut-to-length lines, our +Plus lines provide you with the advantage of precise and fast cut-to-length cutting for special materials (stainless steel, aluminum, copper, chrome-plated, brass, bronze, etc.).

With our +Plus lines, SACFORM offers project-specific solutions for all material types and sizes used in heavy industry, using our cut-to-length cutting systems.

Coil Sheet Slitting Line

Our Coil Sheet Slitting Lines are turnkey systems designed according to our customers’ specific demands and needs.

Our R&D team’s continuously updated and improved design work increases the sheet metal slitting speed on our slitting lines, enabling high-tonnage operations and allowing operators to work faster and more efficiently.

Thanks to the designs developed by its R&D team, SACFORM offers slitting lines produced to international quality standards at much more affordable and accessible costs.

Rolled Sheet Perforation Line

SACFORM/AGMline Perforation Projects can be designed according to many material types and perforation patterns.

In our perforation production line designs, we can offer perforated rolls and plates serving different purposes, and we can also add levelers, slitting, cutting and many external units depending on the job.

Scaffolding Plank Production Line

SACFORM/AGMline Scaffolding Plank Production Line Projects offer the most efficient and high-quality production in terms of technical and design, with solutions including many alternative components.

In the field of safe scaffolding production, SACFORM & AGMline, with its experienced staff and professional technical team, offers you the fastest and most efficient production systems with alternative solution proposals in line with your demands.

Each component of the scaffolding plank production line is designed specifically for the project. The final product offers the possibility of production in the desired dimensions and tolerances without any length limitations.

Suspended Ceiling Production Line

Suspended Ceiling Production Lines are specially designed to produce suspended ceiling panels from rolled sheet metal in the desired size, ceiling type, perforated type, and production capacity.

Thanks to our R&D and design capabilities, we can offer production lines suitable for various applications of metal suspended ceiling systems, including standard clip-in, lay-in, and lay-on models, as well as custom models and sizes according to customer requests.